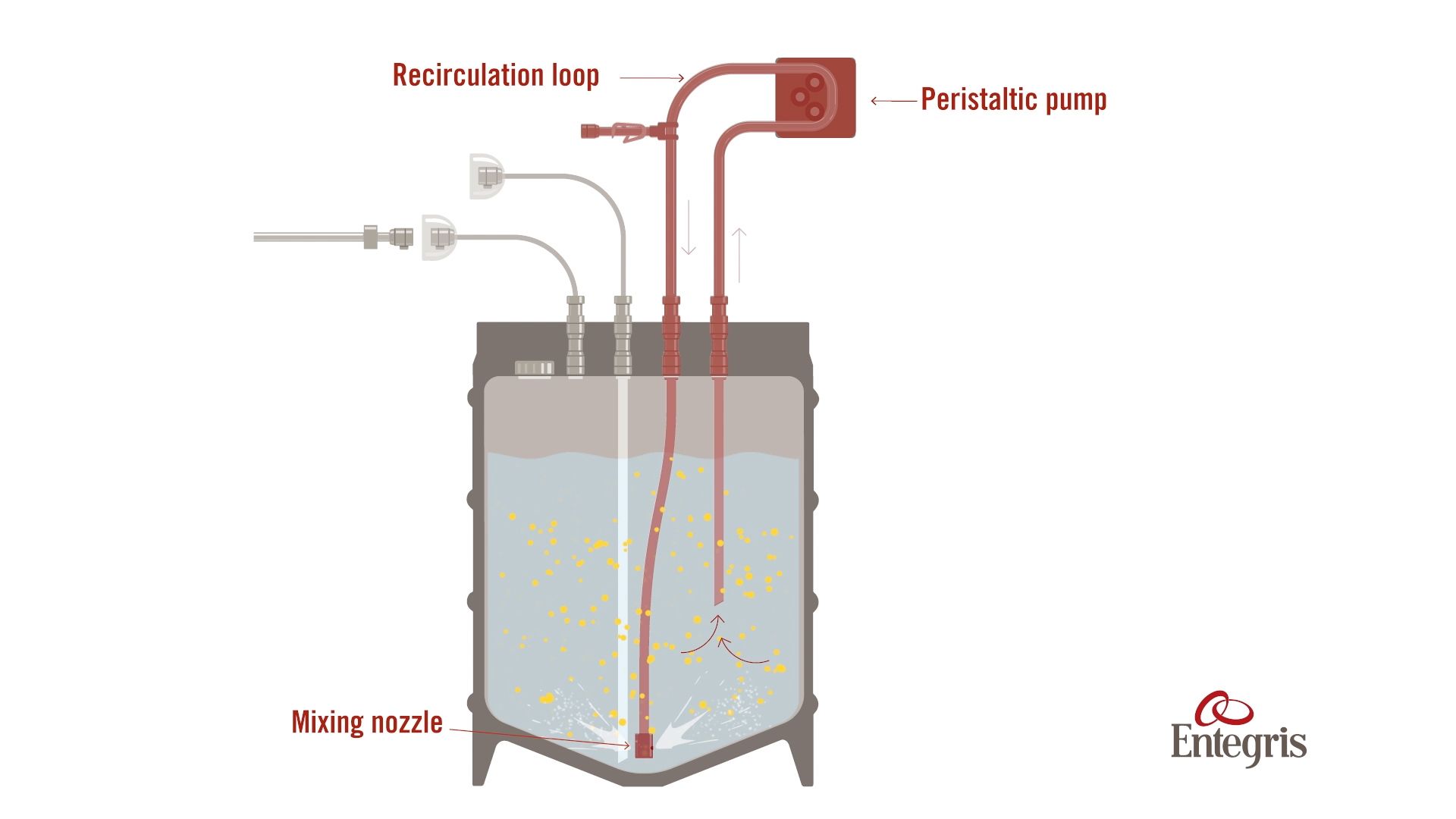

Mixing Systems

Contact your Entegris account manager or

This system creates a completely sterile mixing and recirculation process from start to finish, making it ideal for these single-use mixing applications:

- Buffer preparation

- Media preparation

- Recirculation of homogeneous solutions

- Liquid to liquid

- Powder to liquid

Specifications

| Sizes | 50 L, 100 L, 200 L single-use bags and drums | |

| Drum | Conical bottom, which creates vortex for 100% mixing | |

| Bag film | Flex 100/150, Flex 100/100/150 | |

| Ports | 5 ports | |

| Male and female Luer locks and quick connect inserts and couplers | ||

| Injection dip tubes | ||

| Tubing | Various sizes available to create required pressures | |

| Other | Dip tubes with special stainless steel nozzle available | |

Successfully Opted for software Updates

Single-Use Mixing System